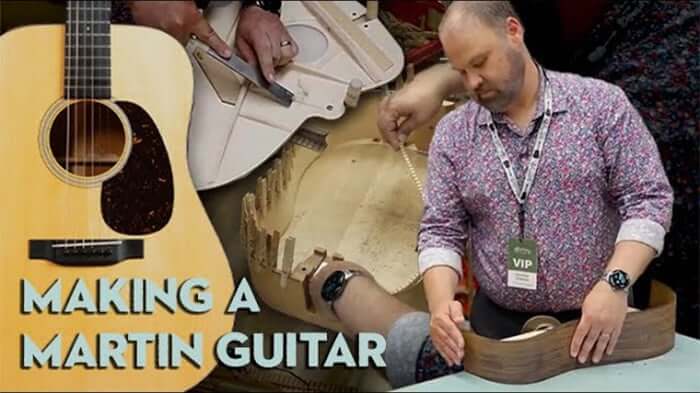

🌅 Stepping Into the Martin Guitar Factory

Walking into the Martin Guitar factory feels like entering a living story of instrument making. Laser cutters hum in one wing, while seasoned luthiers delicately inlay rosettes or gouge braces in another. Every corner reveals a combination of high-precision machinery and human hands shaping wood into music. This factory is more than a production site—it’s a laboratory for innovation, tradition, and artistic expression all at once.

For over 190 years, Martin Guitars has defined excellence in acoustic guitar construction, and a visit to the factory brings that history to life. It's a space where century-old techniques still have a place alongside cutting-edge innovations. It’s not just about building guitars—it’s about building legacies.

🔧 The High-Tech Backbone of Martin’s Craft

One of the most striking contrasts inside the Martin Guitar factory is how seamlessly technology and artisan work blend together. On the one hand, you'll see laser machines cutting tops, backs, and sides with micron-level precision, eliminating wood chip-outs that older methods often introduced. Automated routing units carve binding channels uniformly across batches. CNC machines rough out headstocks, fretboards, and more—each job calibrated for accuracy.

Yet, these machines don’t replace the human touch—they prepare the canvas. After those initial cuts, wood moves to stations where skilled builders hand-shape, refine, and audition parts. They sculpt braces, fine-tune necks, and adjust internal operations in ways no robot can. At Martin, technology accelerates consistency; craftsmanship delivers soul.

The phrase “machine-made” doesn’t mean soulless at Martin—it means “machine-assisted,” giving master builders a more stable foundation to do what they do best. And that ensures every guitar, whether from the Standard Series or the Custom Shop, maintains the warmth, resonance, and identity that players expect.

🛠️ Inside the Custom Shop: Where Dreams Become Guitars

In the heart of the facility lies the Custom Shop, where a Martin instrument is tailored to its future owner. Want a full-thickness “V” neck? Done. Prefer a low-oval profile or hand-selected tonewoods? They’ll accommodate that too. In this realm, builders also hand-bend sides, art inlays, and finish each guitar with a level of care not found on assembly lines.

What sets the Custom Shop apart isn’t just its flexibility—it’s the uncompromising attention to acoustic performance. Everything from top thickness to brace scalloping is adjusted by experienced ears and hands. This is tonal sculpting, not just woodworking.

For truly bespoke instruments, Martin employs high-glue (hide glue) joinery. That approach yields a lighter, more resonant structure, though it demands extra precision and longer cure times. For more everyday models, they may use modern tight-bond adhesives, which offer enhanced durability. Either way, the Custom Shop is where guitars become unique works of art.

And browse available custom Martin guitars at The Acoustic Shoppe:

🎸 Martin Custom Shop Collection

Featured builds:

🌟 Precision in Every Grain and Joint

Walking the floor of the Martin Guitar factory, precision is everywhere. Fret leveling, neck alignment, finish inspection, even glue cleanup—all steps are handled with care. Inlay work is done under loupe eyes, and finishing robots often perform broad tasks before humans step in to polish, inspect, and touch up by hand.

When custom orders arrive—bird inlays, exotic veneers, or heritage designs—they’re routed to specialized luthiers who treat each request as a mini‑masterpiece. The Custom Shop is not just about customization—it’s about telling stories through wood, shell, and craftsmanship.

There’s also an entire department dedicated to final inspections and setup. These aren’t just routine checks—they’re the last opportunity to elevate a guitar from “finished” to “perfect.” Each fret is tested, each nut slot is measured, and each body is listened to and tapped to assess resonance and sustain.

🧰 Behind the Scenes: Repair, Restoration & Modification

One of the most surprising areas in the Martin Guitar factory is the warranty and repair division. This is where damaged, aging, or heavily-played Martins come for rejuvenation. Craftsmen here are not just repair techs—they're master luthiers who can replace tops, reshape necks, or even retrofit inlays on request.

Many guitars sent in for warranty service leave the factory sounding better than when they arrived. Customers also have the option to modify their instrument during the repair process—adding features like custom inlays or new neck shapes. That level of personalization is rare, and it keeps the connection between player and builder alive even years after purchase.

🎶 How Martin Sets the Tone for the Future of Music Retail

What we saw at the Martin Guitar factory wasn’t just great guitar building—it was a lesson in how premium brands should operate in a modern market. Transparency, innovation, and personalization are no longer luxuries—they’re expectations.

Retailers like The Acoustic Shoppe who partner closely with Martin help bring that story to life. Through custom orders, educational content, and customer service rooted in expertise, dealers are now extensions of the Martin experience. And for musicians, that’s a win. It means better access to information, more input in the purchase process, and long-term support for their instrument.

As music retail becomes more digital, the tactile, emotional story behind handcrafted instruments will only grow more valuable. Martin is leaning into that—not just preserving the past, but shaping the future.

🎸 The Intangibles: Feeling the Vibe of the Factory

There's something intangible about spending a day at the Martin Guitar factory. You walk in expecting a tour—you walk out inspired. It’s the smell of mahogany in the air, the hushed focus in the Custom Shop, and the sound of a tap-tuned top being fitted into a body. It's knowing that the guitar you play may have passed through a dozen passionate hands who gave it personality before it reached yours.

The experience deepens the connection between musician and instrument. You begin to hear the story in each note, feel the history in each chord. That’s what makes visiting Martin different from touring any other manufacturing facility—it’s not just about what they build, but how and why they build it.

🔑 Final Thoughts: Why the Martin Guitar Factory Matters

If you're a musician, collector, or even a curious enthusiast, visiting the Martin Guitar factory is a must. It’s more than a behind-the-scenes look—it’s a masterclass in tradition, innovation, and enduring quality.

From hand-bent sides to CNC-shaped headstocks, from high-gloss robots to flecking machines that test every fretboard—Martin’s blend of past and future results in one of the most consistently exceptional instruments in the world.

More importantly, it reminds us that great guitars don’t just appear. They’re carved, shaped, tuned, and loved into existence by people who care. That’s the heart of Martin Guitars—and why the factory stands not just as a workplace, but as a cathedral of craftsmanship.

You can explore Martin's official Custom Shop overview here:

🔗 Martin Custom Shop - Official Site